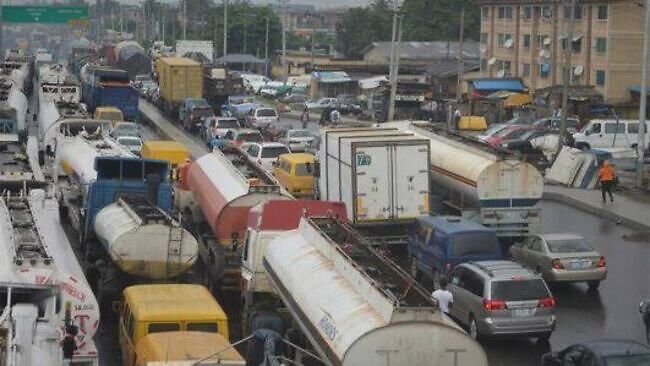

The arrival of a container vessel, GSL Alice at the Lekki Deep seaport at the weekend has led to massive entry of trucks into the Lekki area, apparently scouting for cargoes to lift out of the new seaport. This is even as the truckers have lamented the absence of a Truck Holden Bay at Lekki port, a development that they claimed might lead to trucks parking along the Lekki-Epe-Eleko highway while scouting for cargoes.

Recall that a container vessel, GSL Alice, after discharging some cargoes at Tin-Can port last week, headed for Lekki port on Friday to also offload some cargoes at the new port, signaling the beginning of cargo evacuation processes at Nigeria’s first deep seaport.

Speaking with the Nigerian Tribune exclusively on cargo arrival at Lekki Port, the Chairman of the Association of Maritime Truck Owners (AMATO), Chief Remi Ogungbemi explained that over 500 trucks belonging to his group has headed towards Lekki port in anticipation of businesses.

According to Chief Ogungbemi, “It is a welcome development that we now have cargoes at Lekki Port. Some of our members, about 500 in numbers have headed towards the port since we heard of the arrival of the container vessel. Some importers have been reaching out to our members about cargo evacuation processes.

“However, the problem we might have with the new port is the absence of a Truck Holden Bay.

“The last time we went to Lekki Port on a visit, the operators showed us a massive land space earmarked for the construction of a Truck Holding Bay. However, as at our last check, nothing has been done on that land, so the plan to build a Truck Holding Bay is still in the works.

“Without a Truck Holden Bay, trucks calling at Lekki Port will be forced to park on the highways, and this will clog the roads, thus causing traffic chaos. Since the first container vessel arrived at the weekend, some of our members have moved towards the Lekki Port because there are cargoes that will need to get moved out of the ports.

“Trucks go to where cargoes abound. The issue is just the lack of a Holden Bay for trucks. Without such facility, trucks will park on the roads, and that will become a problem for the port.”

Also speaking on the lack of a Truck Holden Bay at Lekki Port, National President of the Council of Maritime Transport Unions Association of Nigeria (COMTUA), Prince Adeyinka Aroyewun warned that if the roads leading to Lekki Port become clogged, extortion will set in.

“Extortion of truckers is everywhere in Lagos. Our members are being extorted in Apapa, Ikorodu and every other parts of Lagos. The Lekki Port is a new project and cargoes have started arriving at the port.

“As usual, our members will flood the port in search of business. However, if the government allows the road to get clogged with traffic woes, security operatives who will be drafted in to maintain sanity will start extorting truckers.

“That’s how these things work. That’s how it started in Apapa and Tin-Can. We don’t expect Lekki Port to be an exception. The government should just ensure that the roads leading to the new port is not clogged,” the COMTUA National President warned.

With Lekki Port boasting of barges that can also serve as means of cargo evacuation via the waterways and save the ports access roads from unnecessary traffic chaos, findings by the Nigerian Tribune revealed that the expensive nature of movement of cargoes via barges might force many cargo owners to opt for road haulage of cargoes.

Speaking with the Nigerian Tribune exclusively over the option of taking cargoes via the waterways on barges, Dr. Kayode Farinto, acting President of the largest Customs brokerage group in Africa, the Association of Nigerian Licensed Customs Agents (ANLCA) said that more cargoes will leave Lekki port by road rather than by water due to the cheap cost of road haulage.

In the words of the ANLCA acting President, “It is sad that an edifice as massive as Lekki Port is not yet connected to rail haulage. That’s how we do things in this part of the world.

“AlthoughLekki [Port has barges that are ready to move cargoes via the waterways, but how many cargoes will leave by barges?

“It’s more expensive to clear cargoes by barges, so many cargo owners will go for road haulage, and I can’t predict how that Lekki-Epe-Eleko road will look like in weeks to come when different ships start calling at Lekki Port and thousands of cargoes start leaving by road.”

On the plan to implement the Nigerian Ports Authority (NPA) Electronic-Call-Up system, Trucks Transit Parks (TTP), the firm handling the Electronic Call-Up system for the NPA at Apapa and Tin-Can ports explained that the initiative will soon be extended to Lekki Port in weeks to come.

Speaking with the Nigerian Tribune exclusively, Managing Director of TTP, Jama Onwubuariri explained that, “We have been holding meetings with the Lagos State Government over extension of the Electronic Call-Up system, which has been a success story at Apapa port, to Lekki Port.

“We also have meetings this week and I can assure you that very soon, the Electronic Call-Up system will soon be extended to the new port to ease traffic issues around the port area.”

In 2020, Nigeria embarked on an audacious attempt to wrest back lost cargoes from neighbouring and rival West African ports of Togo, Benin and Ghana through the construction of the Lekki Deep seaport in Lagos.

With a main breakwater of 1.5km long with a turning circle of 600 metres, enough for a vessel of up to 16,000 standard containers, and an approach channel of 11 km long, Lekki Port has three terminals: the container terminal, the liquid terminal and the dry bulk terminal. The container terminal has an initial draft of 14 metres, with the potential for further dredging to 16.5 metres. The terminal is able to handle 2.5 million twenty-foot standard containers per year.

The deep-sea port of Lekki is the first port in Nigeria with Ship-To-Shore (STS) cranes. It has three of these container gantry cranes; they belong to the “Super-post-Panamax” group – this means that they can reach and unload the rearmost row of containers even if the container ship is wider than the Panama Canal (49m or 160ft maximum boat beam).

The STS cranes have a fixed rail at the quayside. They can lift 65 tons in twin-lift mode, 50 tons in single-lift mode or 85 tons under a hook. The outreach from the quayside is 61 meters (this corresponds to 25 container rows). – The world’s biggest container ship (as of 2022), the EVER ALOT, has a width of 61,5 meters. The air draft (the maximum height from which containers can be picked up) is 52 meters. Each STS crane generates 300 lux of light, which means that even at night the area around the crane will be nearly as bright as daylight. Cameras will assist.

The layout of the port, including the layout of the approach channel, turning circle, and harbor basins have been derived from optimizations based on port operations, construction costs, and possible future extensions.

Two different breakwater concepts were applied for the main breakwater: A rubble mound with geo-bag core for the near-shore sections and a composite breakwater for the more exposed sections. The main breakwater is 1.5 km long.

The secondary breakwater was replaced by a barrier. The barrier consists of a core from sand, internally fortified by a protective geo-bag layer, a revetment on the harbor side, and an artificial beach on the seaward side.

The port’s computerised system will allow container identification and clearance from the office, and human interaction will be minimal in the physical operations.

When the Phase 2 is completed, the deep sea port will have three liquid berths. The liquid cargo terminal will handle vessels up to 45,000 DWT (dead weight tonnage) and can expand to reach a capacity of 160,000 DWT.

Liquids (like petrol or diesel) will be handled at a tank farm near the port. The docking area is equipped with loading arms. It is also connected by pipelines along the breakwater.

The bulk terminal with available quay length of 300m can accommodate a Panamax class vessel (75,000 DWT